*1 The SSP focuses on the positive events achieved (Safety II), but contemplates, identifies and analyzes the causes of less favorable situations (Safety I).

1- Accident rates remain worrying

In 2017, the International Labour Organization (ILO) estimated that there were about:

2- The little significant developments in the field of safety in enterprises

In Qualiseg's 25 years of experience, there has been no significant development in safety in companies where the team has been providing OSH services.

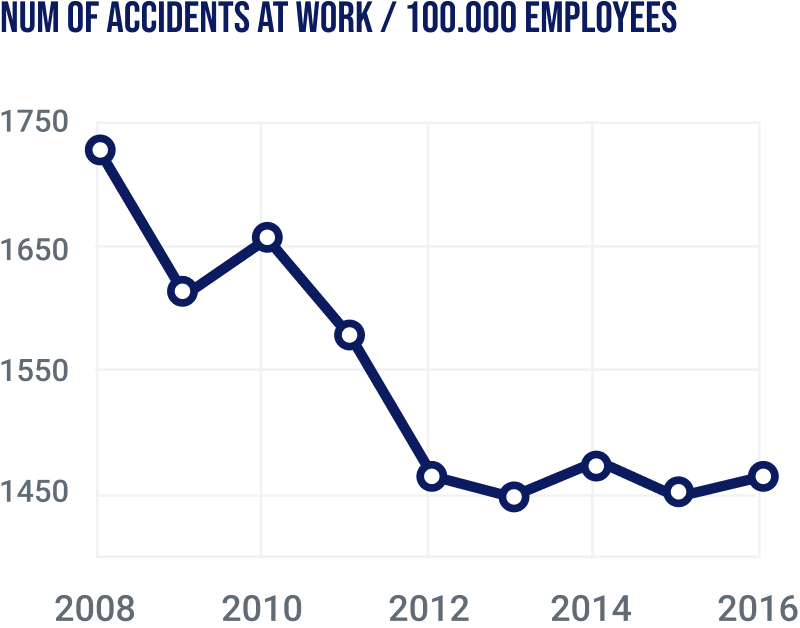

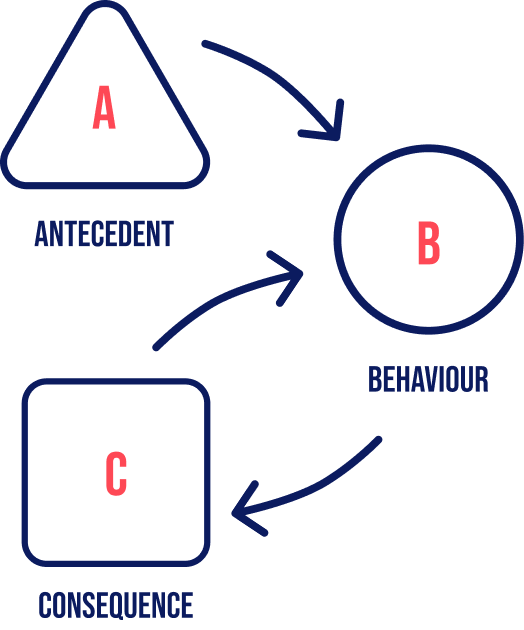

The same is true for many other companies. It is sufficient to observe the national and international accident rates relating to accidents at work.

In recent times there has been a general trend towards the decrease in fatal work accidents. However, nonmortals, less severe but much more frequent, have a stable trend. This trend is accompanied by a slight increase in recent years, as illustrated by the data released by PorData.

3- The opportunity promoted by the INTERFACE Program

The programme aimed to promote the link between companies and higher education institutions to:

In this context, the SSP (Safety Score Permit) tool was created. The system that aims to counter the trend of stagnation of the recent past, guiding safety to reduce work accidents in a sustained way.

To develop the tool it was necessary to consider approaches more adjusted to the reality of the labor market and aligned with the thinking of society.

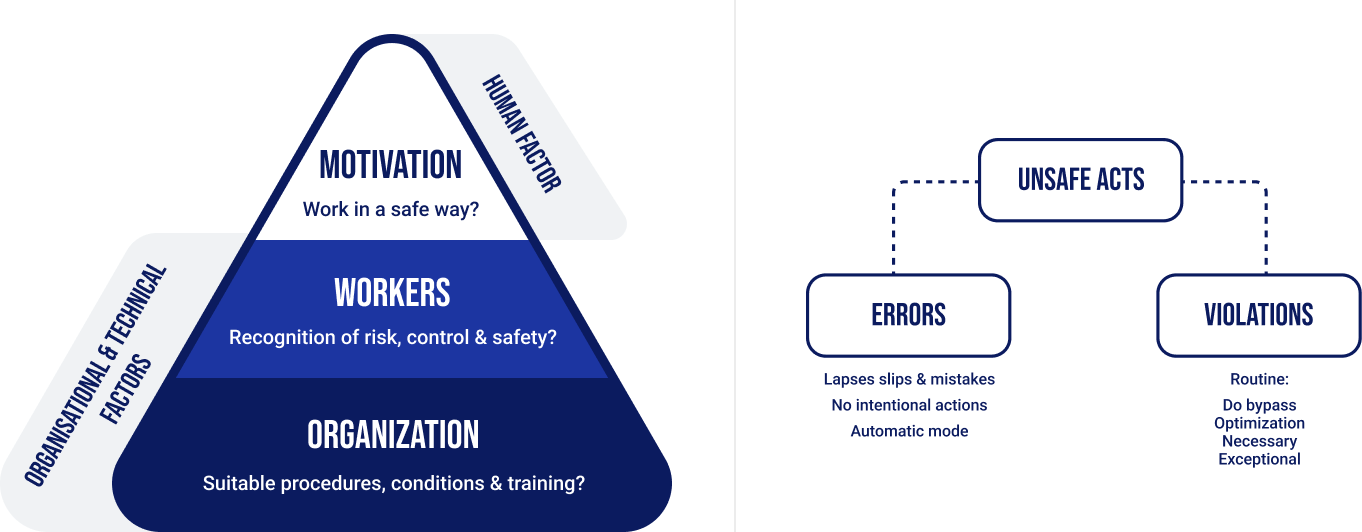

The SSP Points Safety Permit is based on three basic concepts:

Together, these fundamentals allow the direct evaluation of behaviors, using the BBS (behaviour based safety) methodology and the implementation requirements of ISO 45001 (Occupational Health and Safety Management Systems).

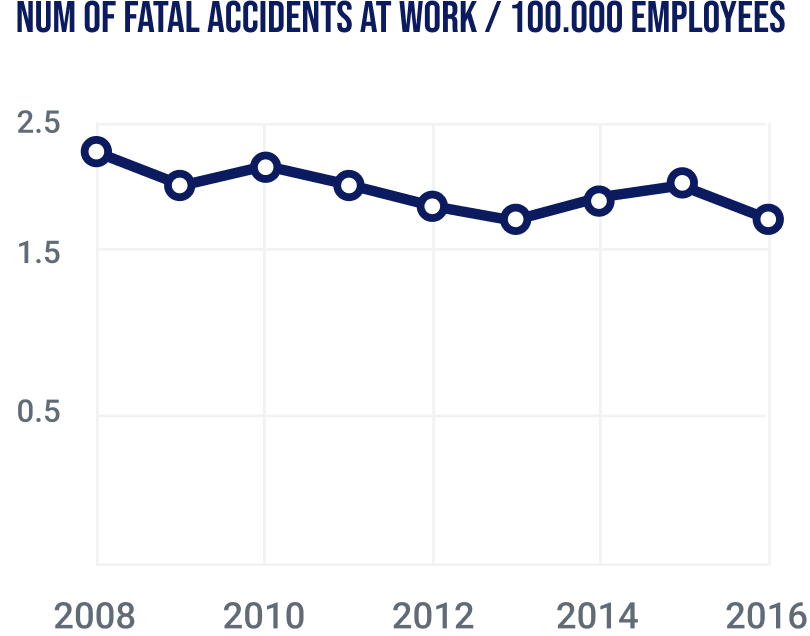

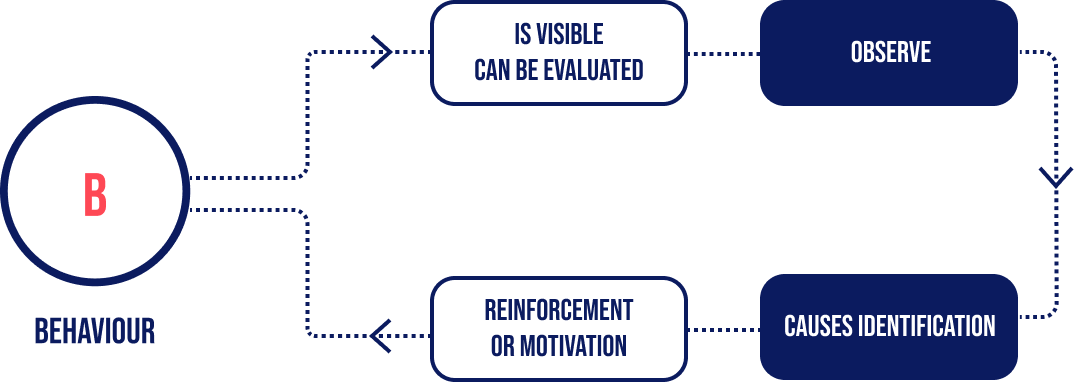

The ABC Model, the basis of the BBS, is also one of the foundations of our solution.

To implement a consistent and sustainable safety culture it is necessary to develop strategies that create and sustain a robust culture. To this end, it is necessary to identify the existing weaknesses, as their identification allows:

For all these reasons, the SSP system is based on the identification and analysis of unsafe acts and their classification. Process that allows the measurement of individual and collective performance of employees, throughout the hierarchy.

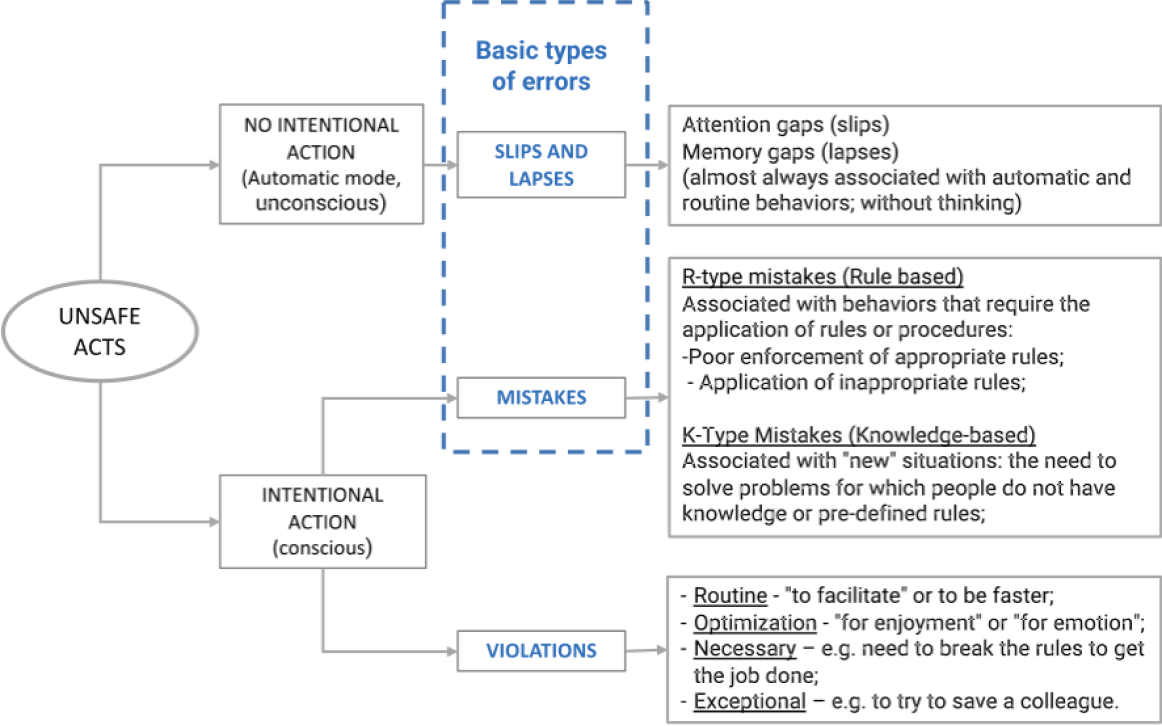

The identification and classification of unsafe acts is done through a process of observing behaviors safely. A process that, in addition to identifying unsafe acts, allows to classify them as errors or violations depending on the severity.

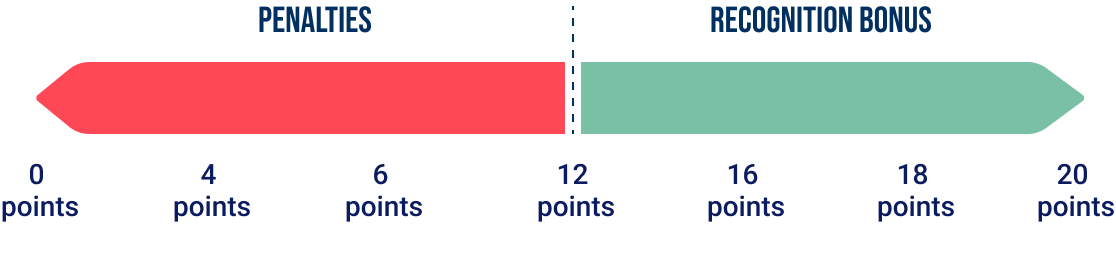

The SSP underlies the allocation of a virtual card with 12 points, in a maximum of 20 attainable. The card is delivered to all workers in the organization, regardless of the position and position held.

There are two types of points, depending on the type of behaviors observed:

Within penalties, unsafe acts are classified as errors or violations, as illustrated below. All deviations are handled. These types of acts support the data and highlight the weaknesses of existing systems and practices in organizations. However, only violations are penalized. This approach plays an important role in improving risk perception as it:

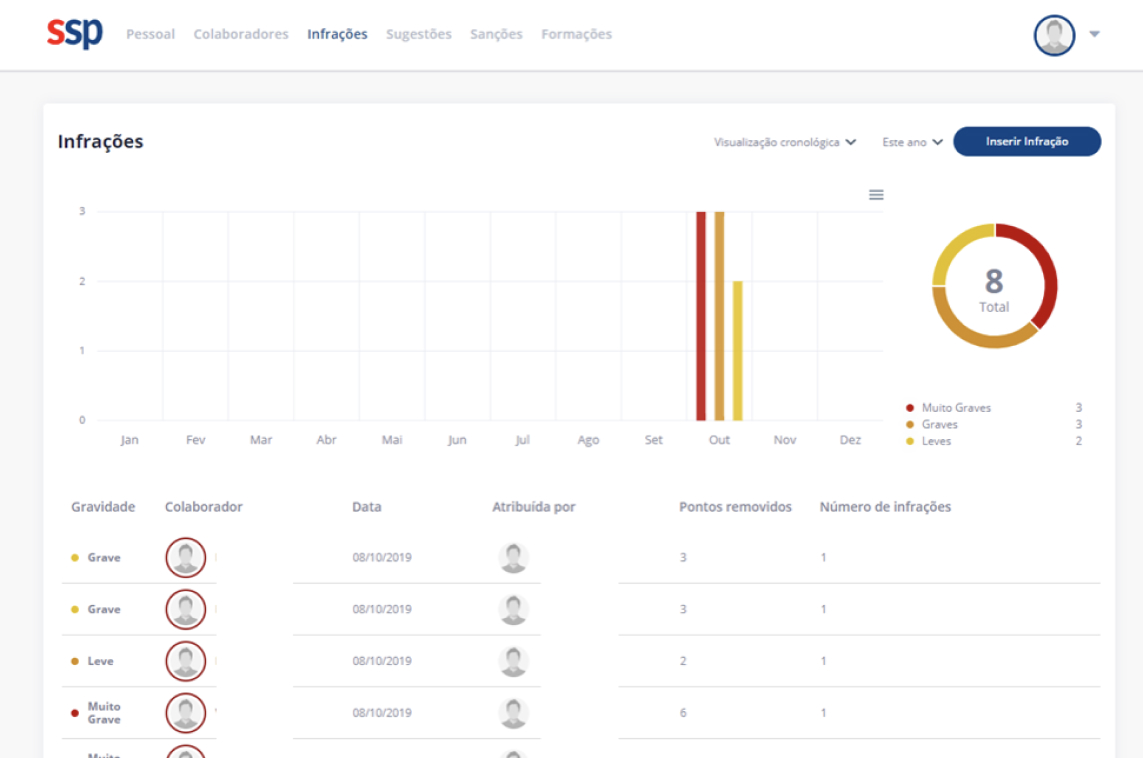

The tool is supported by an IT application that allows to:

To group and identify acts with major deviations, penalties are organized into classes and subclasses. The latter can be adapted to the type of processes, requirements and level of risk existing in organizations. In order to allow the adaptation to the reality of each company, the subclasses will be defined for each case, according to the specificity existing in each company.

The number of points to subtract depends on the severity associated with the type of infraction observed. There are 3 levels of severity: mild, severe and very severe.

In addition, the system has also associated a decision tree. Feature that helps classify violations as errors or violations and assign responsibilities. These may belong to both the worker and other hierarchies, if there is influence or permissiveness in the observed practices.

The pilot implementation of the SSP in large and medium-sized companies proved that the system:

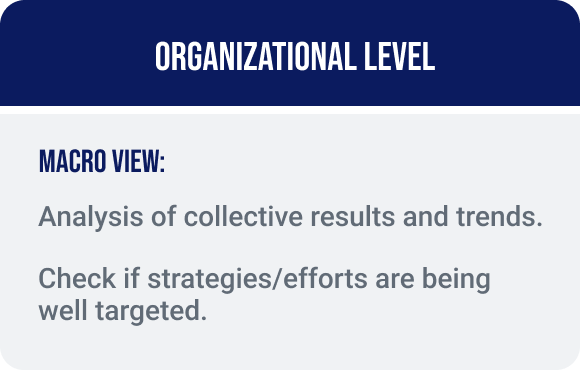

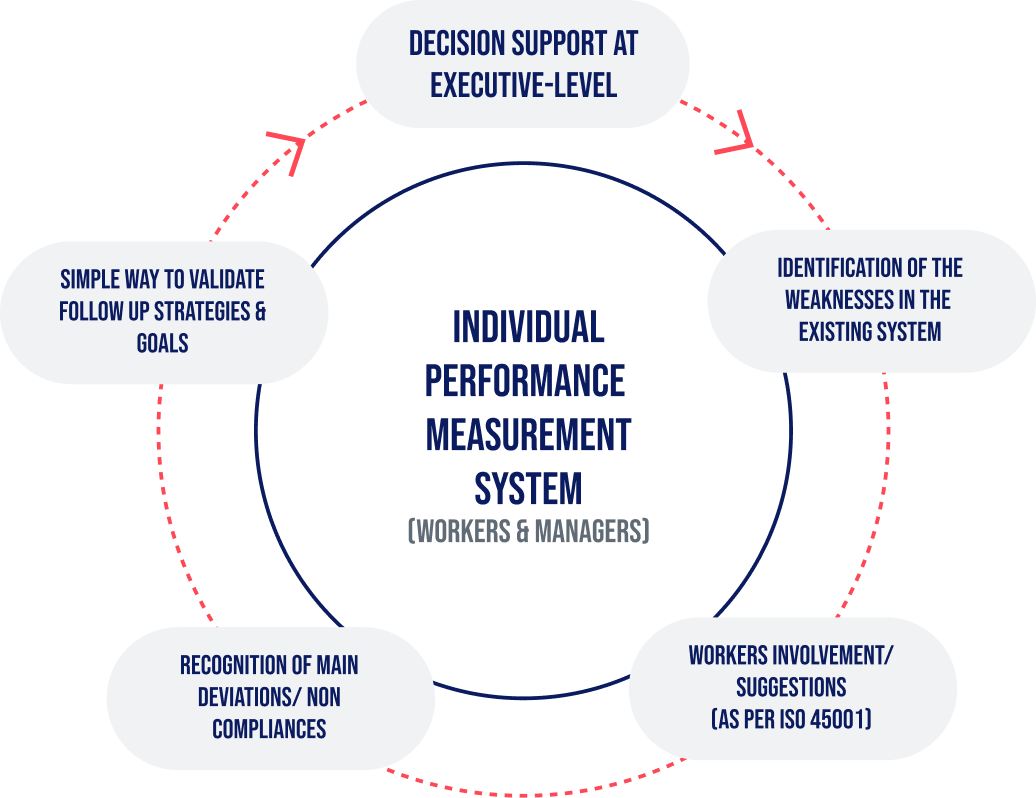

The SSP is managed on a digital technology platform capable of monitoring OSH performance. This solution enables the measurement of individual and collective performance and allows companies to have a vision (global and /or particular) of safety performance.

The SSP tool, as an individual and collective performance monitoring and measurement system, represents a support system. It supports the identification of the main deviations and weaknesses of the system, stimulating the active participation of workers.

Advantages of the Safety Permit by Points:

The Safety Score Permit (SSP) tool was recognized as the best product/service at the 63rd European Quality Congress in October 2019.

The project gained prominence for its innovative nature and incentive to a safer work focused on behaviors. A model that aims to reduce loss in a sustained manner and achieve ZERO incidents.

On October 11, 2020, a presentation event of the SSP tool was promoted, with the collaboration of Portuguese Association of Quality (APQ), where the project deserved positive reviews. These include the assessment made by the Authority for Working Conditions (ACT). According to those present, the SSP exceeded expectations and proved to be a promising tool. There have also been expressions of interest in its implementation.

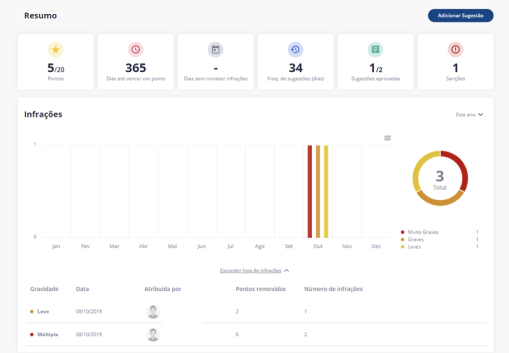

The SSP IT tool allows the introduction of real-time information and real-time tracking possibilities. This follow-up can be done either by workers or by MANAGERS/SST staff, depending on the administration permissions that are granted.

A- Visualization by each individual worker:

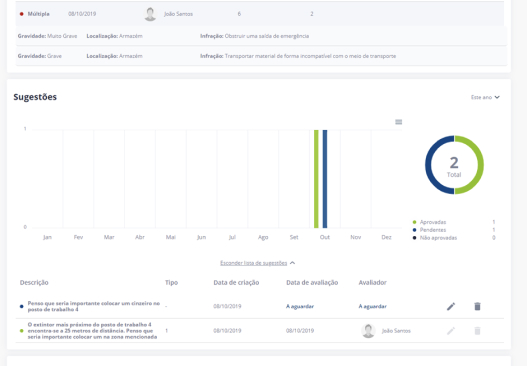

It allows you to observe your entire process - number of points, days without committing infractions, suggestions, and sanctions, if you have any. It also allows you to see the type of infringement committed, description and associated severity.

On the same page there is also information regarding the earning of points by suggestions and/or others that are defined and, at which point they are (validated vs in evaluation).

B- Visualization by the management

On the management side, it is possible to view by worker, all workers, or specific groups of workers, depending on the level of permission that exists for consultation and information management, being able to access all processes and also allowing you to see the number of information per class. Likewise, it has access to the part of the suggestions and/or other initiatives that provide points and let you know where the processes are.

Note: The examples above represent some of the visualizations that the IT system holds.

What do I need to implement The SSP in my organization?

To get the most out of the tool, there must be a process of behavioral observations – safe and unsafe acts implemented. To do this, a group of observers needs to be formed-up, preferably using the BBS methodology. This action will make it possible to identify the root causes and investigate responsibilities if these are found to be infringements. We will be able to help you in this process.

Is the SSP an essentially penalizing tool?

No. The SSP aims to be a tool to encourage good practices and correct deviations, which allows the identification and minimization of weaknesses in existing processes and practices. All to enhance the knowledge and safe acts of workers.

On the other hand, it is intended to encourage workers to be participate proactively and to ensure their own safety and influence positively that of colleagues. They can do this by various means, including support and collaboration, actions or suggestions for improvement relating to working conditions, or how they are managed.

Are all unsafe acts penalized?

No. Most unsafe acts are associated with errors. In the following figure you can observe the process of analysis and classification that supports the decision of classification between errors and infractions.

What kind of bonuses/prizes do you get when you reach the maximum score (20 points)?

The bonuses and the point-making process will be aligned with human resources policies and the SST system in place in the organization. With regard to the prize, the idea is to reward workers in a non-cash way. Starting, for example, by its distinction in terms of communication channels as newsletters. Another example would be to announce workers who reach the level of excellence. Then, complement this distinction with initiatives such as: a dinner with the CEO, a paid weekend or group dynamics abroad. The type of subsidy applied will depend on what is valued by workers and the possibilities in each case.

Are there consequences when 0 points are reached? What?

The establishment of the consequences will be aligned with the policies and processes of human resources in force. The idea is that there is a process of reflection, such as the dispensation of a day with reintegration meeting and analysis with action plan. This analysis examines the motivations for doing safely, as well as what the worker does to perform his work better, in a safe way. After that, you can provide a 2nd card by reintegrating and following the normal evaluation process. If the employee reaches the 0 points again, there may be a process of dismissal, or others of a different nature.

For more information send an email to:

mkt@grupoqualiseg.com

We are available for further clarification and to provide you with a presentation of the tool in more detail.

We will do our best to promptly fulfill your request.

Works based on the following points system, consisting of two paths - bonus and penalty.